The customer is an important company active for years in the production and marketing of brass.

The aims of the project were manifold:

- Automate the input and output weighing processes of the vehicles, freeing the operator present in the switchboard from this activity.

- Automatically direct the vehicles to the correct loading/unloading areas within the company;

- Before the vehicles leave, the system checks that they have actually followed the path assigned to them within the company;

- Check (automatically) the correct positioning of the vehicle above the weighbridge;

- Check the consistency of the actual weights with the weights present in the company management system (Navision);

- Send final weight data to the company management system.

Software & system integration

In this case the LogiCity Factory system is interfaced with a various systems:

- Weighbridge;

- Plate-reader camera;

- Video surveillance cameras;

- Presence sensors (turns, radar, photocells);

- Actuators for bars, sectional doors and traffic lights

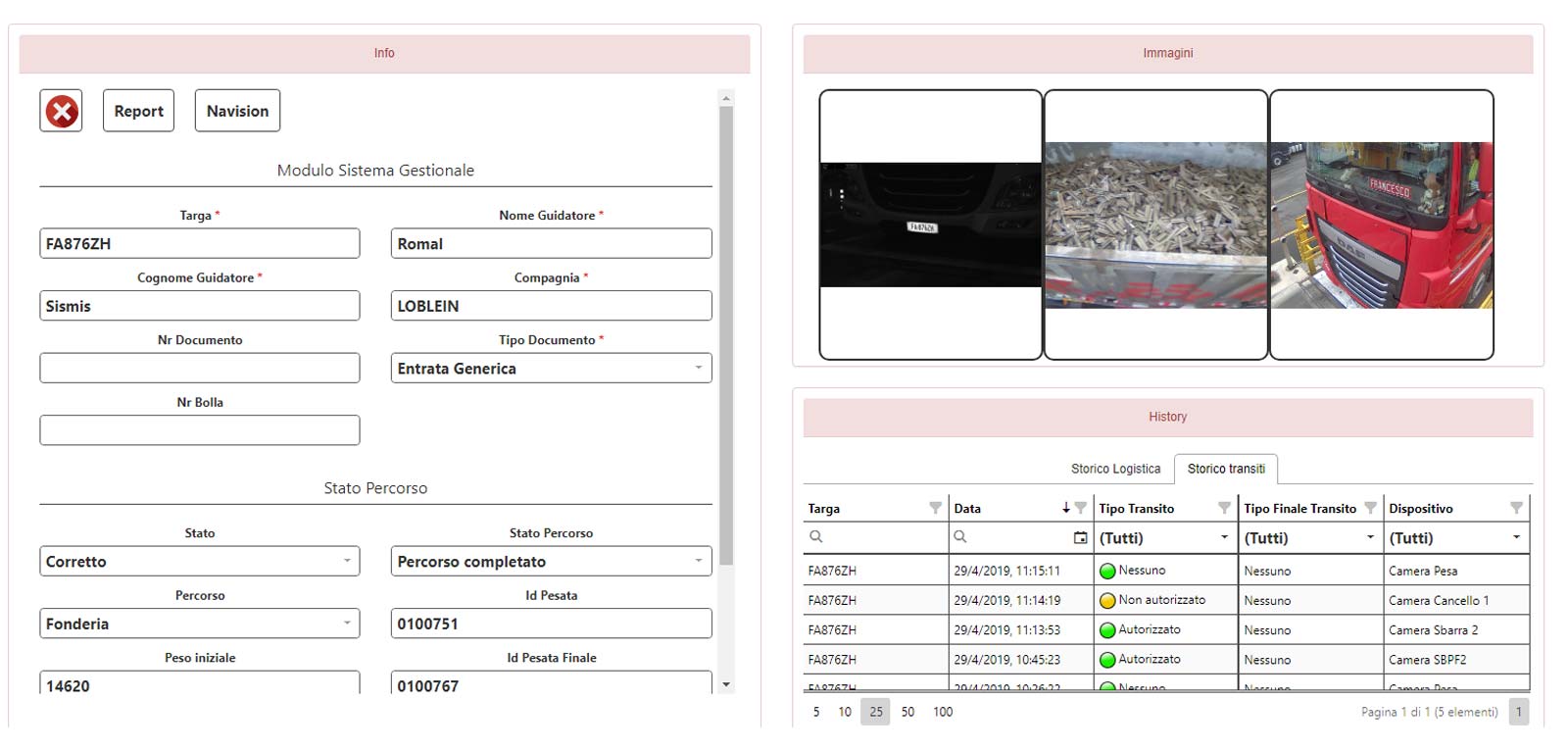

Upon entering the company, the vehicle goes on the weighing system; LogiCity Factory checks the correct positioning and at that point acquires the weight, automatically associating it with the vehicle license plate, and with the images taken by the video surveillance cameras, with front, top and rear shots.

How it works

The acquired data are appended to the list of incoming means. The operator present at the switchboard assigns the vehicle the path to follow based on the operation to be performed (loading bay 1, loading bay 2, scrap yard, etc.)

At the entrance of each loading and unloading area there is a barrier with a license plate reading camera. When a vehicle is assigned a route, automatic access to that area is enabled, only once and within a preset time.

When the vehicle has finished the loading and unloading operations, it returns to the weighing bay. The acquired data are associated with those of the first weighing and of the transits in the loading and unloading areas.

LogiCity carries out a congruence check of all the parameters acquired (expected weight and recorded weight, distance traveled etc.); if the data are correct, exit from the company is enabled, via a license plate reading camera\bar, and the data is sent to the company management system.

Otherwise an alert is sent to the operator in the switchboard and to a user with a higher profile: authorization of the exit can only be carried out by this second operator.

What happens if a plate cannot be read?

A second phase of the project also made it possible to automate the weighing of forklifts transporting boxes of scrap or finished products for internal purposes. Since we were unable to locate the weighing vehicle by reading the plate (the forklifts do not have one), UHF antennas were used; each forklift was therefore equipped with an RFID TAG. In this way, internal weighing was also automated.

LogiCity keeps the history of all the weighs measured and associated images of the various context cameras both present on the weighing system and in the loading/unloading areas. A printed report is also delivered to the driver and made available for consultation by the management.